Make a call

Project Details

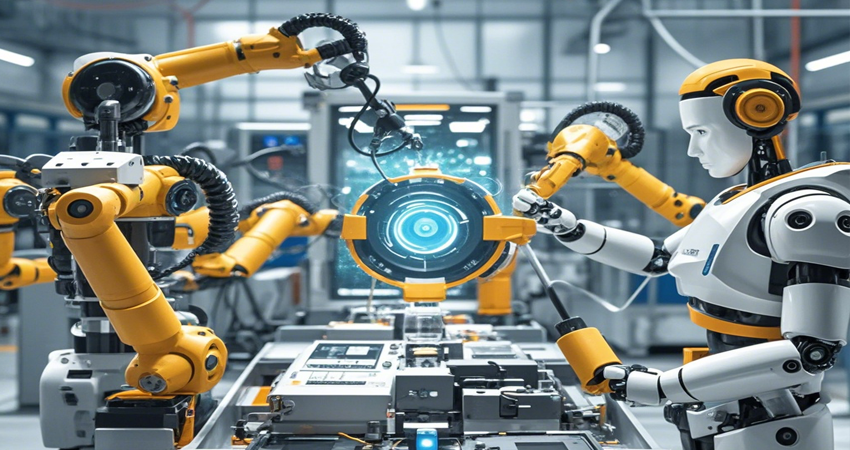

Servo & HIM

Servo and HIM represent different products and fields, respectively. Servo is primarily related to servo systems, providing precise motion control and drive solutions; whereas HIM may be an abbreviation for a brand or company name, with its product and field range varying according to specific circumstances.

Servo Motors

DC, AC, and stepper. Smooth, dynamic, frequent use. Core actuating elements in servo systems.

These are the core actuating elements in servo systems. They come in three main types: DC servo motors, AC servo motors, and stepper motors. DC servo motors are often used in applications requiring high torque at low speeds. AC servo motors, on the other hand, are more efficient and offer a wider speed range, making them suitable for high-speed and high-precision applications. Stepper motors are known for their ability to control position and velocity in discrete steps, providing excellent positioning accuracy. Servo motors are designed for smooth, dynamic, and frequent use, making them essential in systems that require continuous and precise motion control.

Servo Drivers

Drive motors for precise control. Adjust speed and position based on input signals.

Servo drivers are the brains behind the operation of servo motors. They are responsible for driving the motors to achieve precise control over speed, position, and torque. By interpreting input signals from the servo controllers, servo drivers adjust the power supplied to the motors, enabling them to operate as required. Modern servo drivers often incorporate advanced features such as feedback control, regenerative braking, and overload protection to ensure the reliable and efficient operation of the servo system.

Servo Controllers

Receive external commands, adjust servo system state. High-performance computing, multiple interfaces for external device communication.

As the command center of a servo system, servo controllers receive external commands from human operators or other automated systems. These commands can include desired speed, position, acceleration, and deceleration profiles. The servo controller processes these commands using high-performance computing algorithms and adjusts the state of the servo system accordingly. It also communicates with external devices through multiple interfaces, such as Ethernet, USB, or serial communication ports, allowing for seamless integration into larger automation systems. High-end servo controllers may offer additional features such as motion planning, real-time monitoring, and diagnostics to further enhance system performance and reliability.

Human-machine interface module

involves the CPU core module, memory, debugging interface, data transmission, as well as the components for user interaction.

Human-machine interface (HMI) modules are essential components in industrial automation systems, serving as the bridge between humans and machines. They involve a complex interplay of hardware and software components, including the CPU core module, memory, debugging interface, data transmission mechanisms, and user interaction elements.The CPU core module is the heart of the HMI system, responsible for processing user inputs, executing commands, and managing data flow.Data transmission mechanisms enable seamless communication between the HMI and other system components, such as PLCs, sensors, and actuators. User interaction elements, such as touchscreens, keypads, and displays, allow operators to interact with the HMI system.

Build strong relationships

with clients

Take responsibility for our customers, create value continuously,

and become a

trustworthy partner for industrial intelligence and connectivity.