Make a call

Blog Details

01

Thu

Endress+Hauser Promass 300 errors and how to fix them

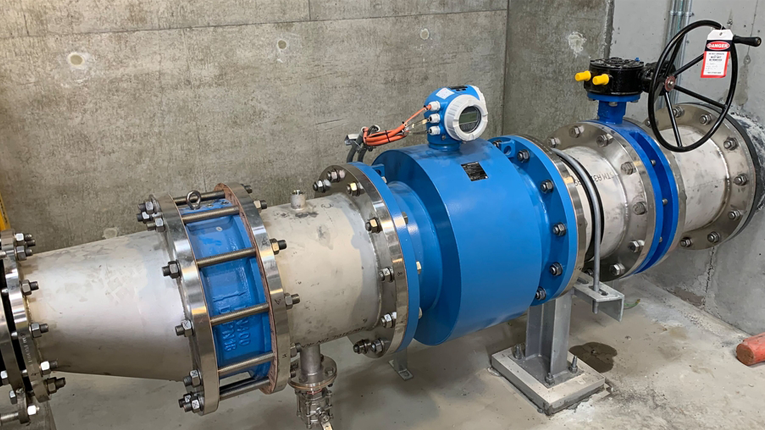

Proline Promass F 300 Coriolis flowmeter

Endress+Hauser Promass 300 errors and how to fix them

Proline Promass [F 300](https://www.cwlyautomation.com/product/1865.html "F 300") Coriolis flowmeter

I. Common Error Types

Meter Error (Fault, F):

Indicates that the measuring instrument has malfunctioned and the measured value may no longer be valid.

Function check (Check, C):

The meter is in service mode or is performing some kind of function check.

Out of Scope (Out of Specification, S):

The instrument is operating outside the limits of the technical specification parameters, e.g. outside the process temperature range or the user setpoint.

Maintenance Required (M):

The instrument requires maintenance, but the measured value may still be valid.

Second, diagnosis and repair steps

View the diagnostic information:

View detailed diagnostic information through the instrument's field display unit or web browser interface. This information typically includes the diagnostic event code, a short text description, and possibly a service number.

Categorize Diagnostic Information:

Categorize diagnostic information based on its weight (severity), typically into highest weight, high weight, and low weight.

Access Remedy Information:

View remediation information for each diagnostic event in the Diagnostics menu or Web browser interface. This information provides guidance for quickly correcting the problem.

Execute Remedy:

Perform the appropriate action based on the remedial action information, such as recalibrating the meter, replacing a defective part, or adjusting a setup parameter.

Reboot the meter:

After performing the remedial action, attempt to reboot the meter to clear possible temporary faults.

Contact Technical Support:

If the problem persists, it is recommended to contact Endress+Hauser's technical support team for further assistance.

III. Examples of specific error fixes

Communication Faults:

Check the meter's communication settings and connecting cables to make sure they meet specifications.

Reboot the meter's communication module or the entire system.

Inaccurate measurement:

Check the calibration status of the meter and recalibrate if necessary.

Check that fluid conditions (e.g., temperature, pressure, flow rate, etc.) meet the meter's specifications.

Sensor malfunction:

Check the sensor for signs of damage or wear.

Replace failed sensor components.

Power supply failure:

Check that the power supply voltage and current meet the specifications of the instrument.

Replace faulty power supply components or check power supply line connections.

IV. Preventive Measures

Regular Maintenance:

Perform regular maintenance and calibration of the meter according to the manufacturer's recommendations.

Monitor Meter Status:

Use the remote monitoring feature to monitor meter status and performance in real time.

Train Personnel:

Properly train operators and maintenance personnel to ensure they understand how the meter works and how to troubleshoot common problems.

Tags:

Our mission

Build strong relationships

with clients

Take responsibility for our customers, create value continuously,

and become a

trustworthy partner for industrial intelligence and connectivity.