Make a call

Blog Details

02

Fri

Wago X-COM®: Revolutionizing Electrical Connections

Wago X-COM®: Revolutionizing Electrical Connections

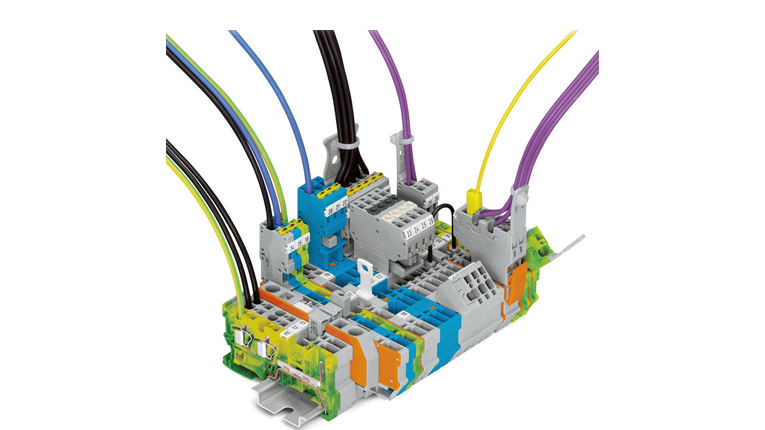

In the realm of electrical engineering and automation, the name Wago X-COM® stands out as a pioneering force. Since its inception in 1997, the Wago X-COM® series has been at the forefront of innovation, combining the functionality of plug-in connectors and rail-mounted terminal blocks to meet the diverse wiring needs of various industries.

### Overview of Wago X-COM®Overview of Wago X-COM®

The Wago X-COM® series encompasses a wide range of products designed to cater to different applications. These include specially engineered rail-mounted terminal blocks serving as the foundation, offering various single-wire, double-wire, and angled-hole connectors. What sets Wago X-COM® apart is its ability to provide complete electrical safety even when disconnected, ensuring that current planning becomes more straightforward and efficient.

Core Features and Benefits

### Versatility and Compatibility Wago X-COM®**1. Versatility and Compatibility Wago X-COM®

The Wago X-COM® system is renowned for its versatility. It can be used in electrical control equipment, frequency converters, thyristor combinations, motor soft starters, motor controls, filters, power devices, DC stabilized power supplies, uninterruptible power supplies (UPS), electrical cabinet door wiring, and more. The series includes base terminal blocks such as ordinary, double-deck, and automatically grounding terminal blocks that form electrical connections with guide rails. Furthermore, functional base terminal blocks like disconnectable ones with diodes or LED indicators are also available.

Moreover, Wago X-COM® offers compatibility with TOPJOB® S rail-mounted terminal blocks and their accessories, providing users with a seamless integration experience. The X-COM® S-SYSTEM, in particular, comes in two different terminal block widths: 3.5 mm (2020 Series) and 5.2 mm (2022 Series), catering to various conductor sizes up to 4 mm² (12 AWG).

### Advanced Connection Technology Wago X-COM®**2. Advanced Connection Technology Wago X-COM®

At the heart of Wago X-COM® lies the Push-in CAGE CLAMP® technology, which has been proven reliable through billions of connections. This technology facilitates quick and easy wiring of solid, stranded, and ferruled conductors. The cage spring connection ensures a secure and reliable connection in all application areas.

### Safety and Error Prevention Wago X-COM®**3. Safety and Error Prevention Wago X-COM®

Safety is paramount in electrical connections, and Wago X-COM® excels in this regard. The system features 100% mismating protection, which prevents connectors with the same pole numbers from being incorrectly connected. Additionally, the connectors provide complete touch protection when disconnected, enhancing overall safety.

The X-COM® series also includes locking levers and strain relief plates for mechanical protection. These features, coupled with the system's robust design, make it suitable for use in hazardous areas with appropriate approvals.

### Ease of Maintenance and Testing Wago X-COM®**4. Ease of Maintenance and Testing Wago X-COM®

Maintaining and testing electrical connections can be time-consuming and costly. However, Wago X-COM® simplifies these processes. Pre-assembled components save time and money during production, assembly, operation, and maintenance. Furthermore, test slots for test plugs in female connectors and carrier terminal blocks allow for easy testing, ensuring that the connections remain reliable over time.

Applications and Industries

The versatility of Wago X-COM® makes it ideal for a wide range of applications across various industries. From railway systems and industrial automation to modern building facilities, the series provides reliable electrical connections that meet the demanding requirements of these sectors.

In switchgear and control applications, for instance, Wago X-COM® ensures time- and cost-saving system wiring. Its ability to handle high currents (up to 32A at 500V) makes it a cost-effective alternative to heavy-duty connectors in environments that do not require high levels of protection but demand electrical compatibility.

Tags:

Our mission

Build strong relationships

with clients

Take responsibility for our customers, create value continuously,

and become a

trustworthy partner for industrial intelligence and connectivity.